Best Inventory Management Software in Bangladesh – 2025

In today’s fast-paced business environment, an efficient inventory management system is no longer a luxury—it’s a must. A local shop or a full-fledged international company, coordinating inventory effectively means having the products available at the right time, minimizing costs wherever possible, and most importantly, keeping your customers happy. The heart of this system is the Inventory Management System (IMS), which assists companies in maximizing use, tracking products, and predicting demand. In this blog, we will drill down into the need for an IMS, its mechanism, different types, and the pivotal role it plays in organizations.

Inventory Management System (IMS)

At its heart, an inventory management system is a type of software or digital tool that can keep a record of the flow of products and services from the business itself to the customers. This is about the full life cycle of a product — from the time it enters the warehouse or store to the time it is sold or used. It ensures a company has the optimal amount of inventory at the optimal time, minimizing both stockout and overstock situations.

IMS may take the form of modest applications (e.g., a spreadsheet) to very large systems that are connected with other internal or external systems, including supply chain, finance, and sales. PantryChem also fulfills the same purpose, no matter the scale of operation: real and accurate data for businesses to make better and timely informed decisions.

How Does an Inventory Management System Work?

Inventory Management Systems do this by automating the various inventory-related processes. These traceability systems keep track of product flow at every stage from reception to sale. The following is a description of the main components of an IMS:

Barcode and RFID scan: The majority of the new IMS systems have barcode or RFID technology. This way, companies can easily and accurately trace goods as they travel through the supply chain. Workers can scan barcodes at various points from receipt of goods to shipping, or even during stock counts, for real-time accuracy.

Stock Level Monitoring The IMS must monitor the stock level. Stock levels will automatically be updated by the system when the product is sold or stock is committed. It can also create reorder points to automatically have purchase orders generated when stock drops below a certain level.

Basic process flows Order management Most of the IMS systems interface with the order management system, making order booking seamless. That way, when orders are placed or fulfilled, businesses can update the inventory count automatically. It is also helpful in controlling backorders and distribution of stock.

Inventory Prediction: Sophisticated IMS solutions out in the marketplace offer predictive analytics that predict demand using sales history, trends, and seasonality. This characteristic is useful for businesses so that you can anticipate stocks to buy ahead of time in both overstock and understock.

Real-Time Tracking and Reporting: IMS enables real-time tracking of inventory information for rapid, informed actions. The majority of systems also have reporting features that provide detailed inventory and stock levels, turnover, order history, and sales trends to help managers better manage the business.

Supply Chain Integration: Several IMS systems can be integrated with other business management systems such as ERP and CRM systems. This unified data access ensures a consistent stream of information between different departments, which promotes better decision-making and communication.

Inventory Management Systems Types

Inventory management systems have different, scalable solutions depending on the size of your business and its complexity. They come in various forms, including

Manual Stock Control - The most basic approach, typically involving the use of spreadsheets or paper-based systems to manage inventory. It’s cheap and easy as pie, but it’s also open to human error, time-consuming, and does not scale as a business grows.

sBarcode Scanning Systems: In these systems, one places barcode labels on products. When workers receive, sell, or transfer stock, they scan the barcode, and the inventory record is updated. Although faster than manual techniques, this system still relies upon physical scanning.

RFID Systems: RFID tags offer the possibility to keep track of inventory automatically, without having to perform line-of-sight scans. RFID can read at a distance, improving processing time and minimizing errors. They are generally found in larger businesses that carry large quantities of stock.

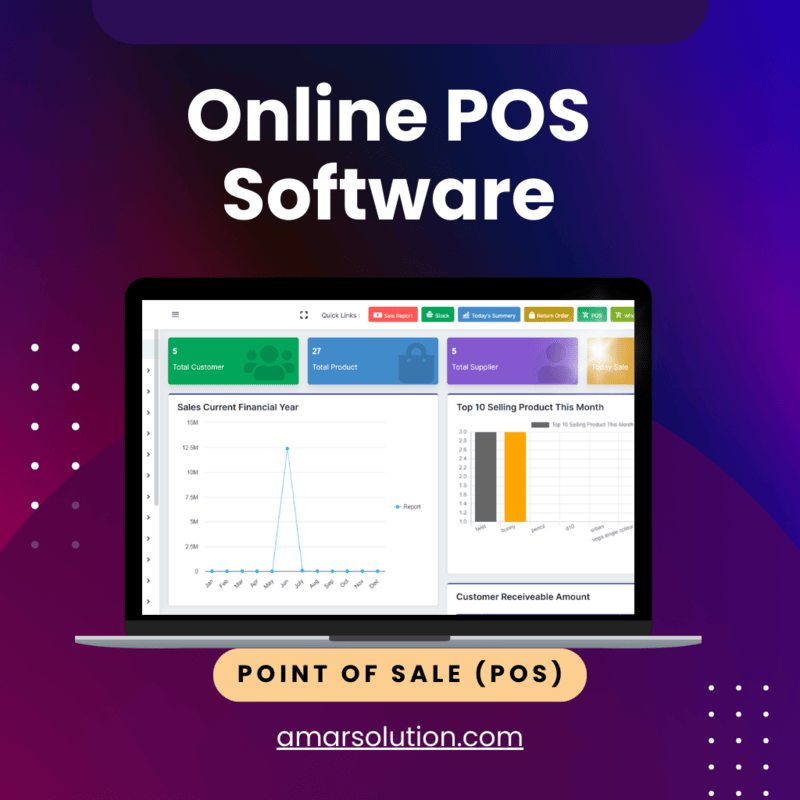

In the Case of Web-Based IMS: Web-based IMS systems give businessmen the power to access the inventory-related report from anywhere with an internet connection. These platforms often connect with other software, so you have a one-stop shop for managing inventory, orders, sales, and reporting. They scale well, and lending them, particularly based on Internet technologies, is suitable for any size of business.

Enterprise Resource Planning (ERP) Systems: ERP systems integrate inventory management with other functionality of the business, such as finance, human resources, and customer relations. Businesses with multiple processes and complex operations usually use them.

Why is the management of inventory so important?

Inventory Management System: Key to the Success of Any Business. Here’s why it matters:

Maximized Cash Flow: By eliminating unsold inventory, businesses avoid tying up precious capital. An inventory management system (IMS) makes sure firms hold just the right stock, improving cash cashflow and controlling excess costs.

Reducing Stockouts and Overstocks: Not having enough stock means lost sales opportunities, but too much stock incurs storage costs and keeps products from selling. Keep stock balanced and ensure that stock is available when needed without overbuying.

Precise Forecasting: Based on past data and trends, Estoque offers the means for businesses to forecast demand more precisely. This leads to better purchase decisions and better preparedness for peak seasons and to mitigate the risk of under- or overstocking.

Efficiency: Automation of inventory monitoring and management tasks saves time and minimizes errors. This results in the ability to complete orders more quickly, efficiently, and with better use of resources.

Customer satisfaction: An effectively managed inventory means orders can be fulfilled immediately. Certainly for the modern customer, demand is based on the expectation they have that when they want a product, it will be in stock, and with an IMS, this particular demand will be met; thus, they are more likely to return to buy again and more likely to remain loyal to the business.

Data-driven decision-making: Leveraging real-time data and analytics, an IMS helps companies make smart decisions about pricing, ordering, and inventory levels. This measured approach minimizes guesswork and yields better strategic planning.

Advantages of Using an Inventory Management System

A business can benefit from a multitude of advantages brought by an IMS. Here are several of the most significant benefits:

Cost savings: With successful inventory management, the need for unnecessary stock is reduced, which lowers storage costs, avoids spoilage (where applicable for perishable goods), and reduces the financial risk of excess stock being kept.

Time Saving: By automating inventory-related operations—stock tracking, generating supply requests, stock takes, etc.—you’re saving your time and reducing inaccuracies in manual data entry. Workers can concentrate on other job responsibilities, thus ultimately increasing productivity.

Greater Accuracy: With an IMS in place, your restaurant greatly lessens the likelihood of human error, which is inevitable during manual inventory management. Real-time updating ensures that your data is always accurate, minimizing errors in orders and stockouts.

Scalability: As your business expands, handling inventory by hand only gets more difficult. An IMS is scalable, which means you can deal with increasing volumes of stock, a greater number of products, and more intricate supply chains without losing efficiency.

Real-Time Visibility—Through an IMS, businesses can have a real-time view of inventory. And because everything is in view, it keeps managers better informed so they can make decisions in a timely manner; for example, ordering more inventory, fulfilling customer orders, or changing pricing.

Stronger Relations with Suppliers: With the help of more accurate forecasting and order tracking, companies can stay in touch with suppliers more efficiently. IMS can automatically create purchase orders, facilitating closer supplier relationships and reducing the risk of a supply chain disruption.

Inventory management systems—the problems and issues

Despite the many advantages of an IMS, there are difficulties in deploying it:

Initial Expense: Upgrading to an advanced IMS can be costly, especially for small businesses. The startup cost can be quickly recouped, however, and many find the new efficiency of the process well worth the added expense.

Training: Staff need training in order to use the system efficiently. The effect of the system may not be the same if the recipients are inadequately trained.

Complexity of implementation for large operations: When the supply chain is highly complex relating to multiple supply chains, integration of an IMS with other tools such as ERP or CRM may be complex and may to be heavily customized.

Dependence on Technology: If you are using the automated service, a technical problem or downtime could bring everything to a standstill. Having a plan B and regular maintenance is key to keeping the system flowing with minimal glitches.

Conclusion

An inventory management system is more than just software—it’s a strategic asset that can bring efficiency, productivity, and cost savings to any business operation. With the industry at such a high level of competitiveness, misuse of time down to moving, swapping, and logging in and out of third-party systems is now costing you money. Between small businesses wanting to optimize and larger businesses forced to manage complex supply chains, the move to an IMS can allow businesses to stay one step ahead. Implementing an IMS can be difficult, but the advantages far outweigh the difficulties, and an IMS is an essential component of any business operation today. The future of inventory management As technology continues to develop, the future of inventory management looms bright as smarter systems will provide more intricate features and be even more advanced than ever before.

.jpg)